Tubes — some experiments

- This topic has 14 replies, 3 voices, and was last updated 3 years, 5 months ago by

Lamar.

-

AuthorPosts

-

February 16, 2020 at 10:41 pm #11188

Clep

ParticipantLike so many before me, I tried and failed to find a source for flexible tubing as is commonly used for melodicas, or alternatives, etc. Even places like this had nothing useful when I inquired.

But I found that if I used half-inch (outer diameter) rubber tubing from the hardware store (5/16 I.D., .1″ walls), I could wrap it in techflex (I used 1/4″ techflex, and needed about 46″ of it to cover about 2 feet of rubber tubing.) I taped the ends with 3M black electrical tape (generic vinyl electrical tape is terrible) which is necessary because the techflex will rapidly unravel wherever it is cut.

The idea was to have the smooth inner walls and flexibility of the rubber hose, but use the tech flex to constrain the expansion (the 1/4″ techflex is basically maxed out when expanded over the 1/2″ hose) since I expected the rubber hose to blow up like a balloon when air pressure was applied.

I was super proud of the result… in fact, the techflex/tube combo has even less inflationary stretch than the original corrugated tubing, and it looks pretty good, all things considered. But then I tested a piece of the rubber tubing and realized that just bare it has less stretch than the original corrugated tube. So, except for the aesthetics, there doesn’t seem to be much need for the techflex. It does make the tubing slide a bit easier, so it won’t hang up on clothing as much, etc, but now I’m reaching. 🙂

And there is a potential drawback: at first it seemed like the rubber hose was collecting way more condensation than the corrugated tube, necessitating a blow-out every other tune I played. I don’t know if this is because the rubber hose takes longer to warm up to breath temperature, or because the corrugations in the original tubing tend to slow the condensation from running down the inside of the tube. I’m not sure yet if it’s a bug or a feature… maybe it keeps more of it out of the melodica itself.

It also remains to be seen how long the electrical tape lasts…

Here is a picture. From left to right: the 1/2″ rubber hose, the 1/2″ rubber hose wrapped in techflex with a 3d-printed replacement elbow fitting for a Hohner Piano 36, the original tubing with a 3d-printed elbow, the original (repaired) elbow with a 3d-printed elbow, and a suzuki tube and fitting:

Here’s a close up of the techflex tube:

Here’s the link for the .stl file for the elbow: http://caseyconnor.org/pub/image/melodicas/hohner_mpiano_36_elbow_v2.stl

February 16, 2020 at 10:44 pm #11189

February 16, 2020 at 10:44 pm #11189Clep

ParticipantUm… don’t know why the IMG tags didn’t work… here they are in link form:

https://caseyconnor.org/pub/image/melodicas/melodica_tubes.jpg

https://caseyconnor.org/pub/image/melodicas/melodica_techflex_tube.jpg

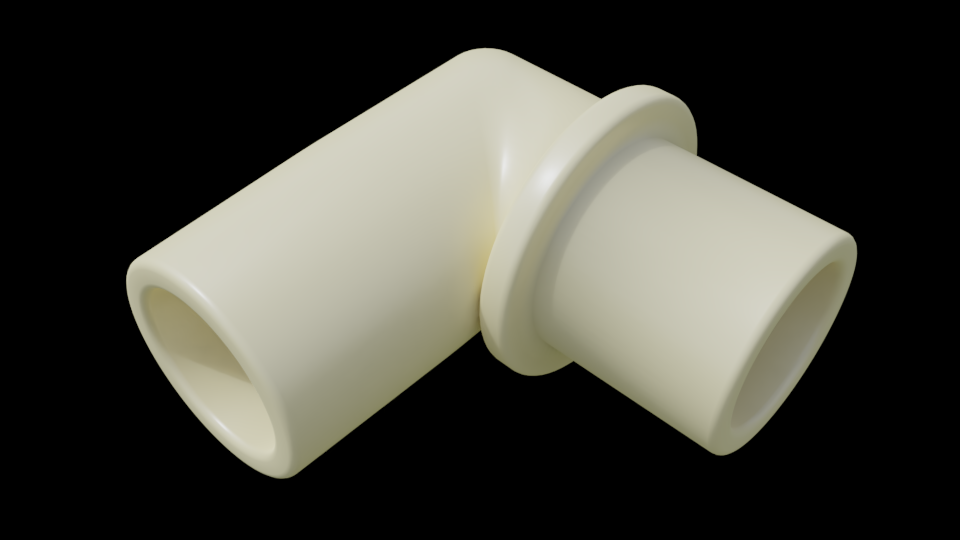

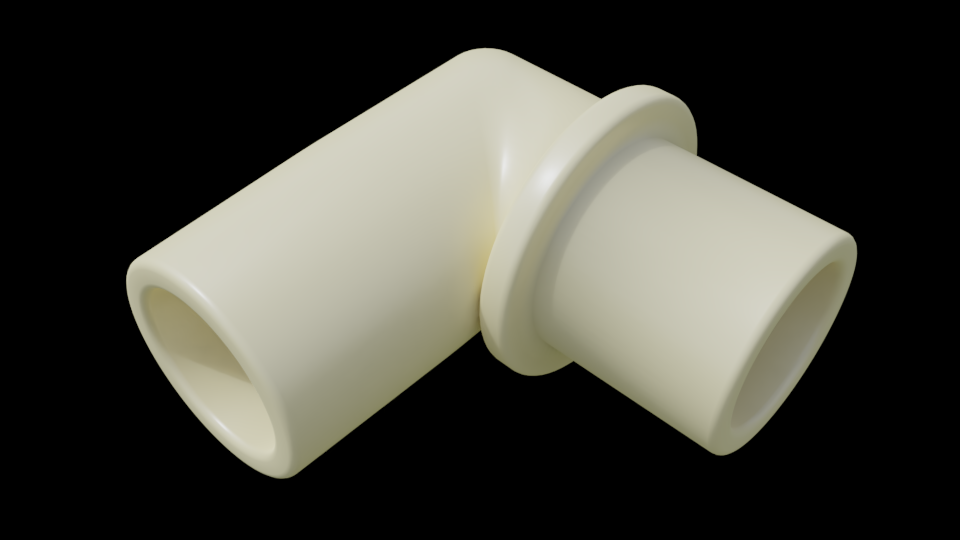

https://caseyconnor.org/pub/image/melodicas/hohner_mpiano_36_elbow.png

February 16, 2020 at 10:46 pm #11190Clep

ParticipantAh, maybe the https… let’s try http:

February 16, 2020 at 10:47 pm #11191

February 16, 2020 at 10:47 pm #11191Clep

ParticipantArgh, nope. Here are plain links with no https:

http://caseyconnor.org/pub/image/melodicas/melodica_tubes.jpg

http://caseyconnor.org/pub/image/melodicas/melodica_techflex_tube.jpg

http://caseyconnor.org/pub/image/melodicas/hohner_mpiano_36_elbow.png

February 18, 2020 at 10:44 pm #11195 KevinParticipant

KevinParticipantVery interesting Clep. I’ve had pretty good luck with the surgical tubing. The drawbacks I’ve found is if it gets bent at an extreme angle it will sometimes kink up and block airflow also any accidental pressure on it will block airflow.

February 18, 2020 at 11:26 pm #11196Clep

ParticipantYeah this stuff doesn’t seem to kink too easily… the walls are pretty thick. And I think one bonus of the techflex is that it helps a little with that as well.

September 9, 2020 at 4:38 pm #11708Antonio Freixas

ParticipantThis is an old thread, I know, but I’ll make some comments anyway.

I didn’t think there would be any inflation of the corrugated tube at lung pressures. But I found that if I closed off the far end and blew really hard, my tube stretched a bit.

I’m trying to think if this stretch would be a problem. When one or more reeds are open, I don’t believe you will get any stretch (you’ll increase the air flow instead), so I don’t see how it could be a problem when you are playing.

If you continue to blow when all reeds are closed off, you’ll pack a bit more air into the tube. [Since air is incompressible, you’ll only pack more air if the tube can stretch. However, this is only if you’ve got a great seal. When I tried it, I found the seal is the weak point–it releases air before the tube can stretch.] As soon as you play a note, the pressure in the tube will drop immediately. I don’t think there is enough energy in the tiny volume of air in the tube to even sound a single note. You need to continue supplying pressure (by blowing) to produce any sounds.

So why worry about this or invest time and money into work-arounds? Is there a measurable effect you’ve observed? It seems to me that if you are blowing hard enough to be concerned about the tube stretching, you are applying a lot more pressure than the reeds might like.

September 17, 2020 at 8:12 pm #11738Clep

ParticipantHi Antonio — the motivation for the project isn’t the stretching, it was just the fact that the tubes wear out (start cracking, etc) and I wanted a way to replace them without having to buy expensive melodica tubes on eBay.

The stretching issue probably isn’t a big deal, no, but the reason people care about it is that the “responsiveness” of the melodica is associated with less stretch and a more direct connection to the instrument. See for example the people that won’t use tubes (and instead use the mouthpiece) in part because of the softening of the attack of notes due to the compression of air in the tube and the stretch of the tube. See also some melodicas that use rigid metal tubes instead of plastic, etc. For me, the corrugated tubes definitely have a little bit of stretch. I don’t know if I could tell the difference in the instrument in a blind test, but I still wanted to find a tube that had minimal stretch, and the rubber surgical tube seemed like it would suffer in that department. I was happily surprised that it wasn’t an issue.

Air is definitely compressible (see e.g. air-based shock absorbers, 90psi bike inner tubes, etc.) — perhaps you were thinking of water, which, while technically compressible, is effectively not compressible.

September 18, 2020 at 3:18 pm #11741Antonio Freixas

ParticipantOk, got it! Melodica tubes seem cheap to me, so it’s surprising that people would be looking for something cheaper. For example, I bought a tube and a short, hard mouthpiece for $USD 8.88 on Amazon recently.

In any case, you identified a hole in my knowledge about an interesting topic, so thanks.

Some background: in fluid dynamics, gasses and liquids are considered fluids. Air is a fluid and so is water. If you look up “is air compressible”, you’ll find a lot of references to air being incompressible at low velocities (below Mach 0.3). The bike pump example is a counter-example, so that’s where the hole in my knowledge was. I found a detailed explanation at https://physics.stackexchange.com/questions/257851/can-air-be-considered-incompressible-as-long-flow-velocities-are-less-than-100-m. The short answer seems to be that below Mach 0.3, the error in fluid dynamics formulas that assume air is incompressible is small and air can be treated as incompressible when studying its flow.

Fluid dynamics is what you would use to analyze air flow through a melodica–at least, when one or more reeds is open.

Pressure and compression are two different things. Pressure is a force applied over an area while compression is an increase in fluid density, where fluid density is mass per volume. In a sealed container, for example, you could increase the pressure just by heating the container but it won’t change the fluid density.

When you blow into a mouthpiece, you are definitely applying a force, so you are applying pressure.

But can I compress air with just my lungs? I’m still working to find an answer. I think it’s “yes”, but you can’t compress it much. As a test, I tried to see if I could compress the air in my melodica. I put on a hard mouthpiece and blew as hard as I could without pressing any keys. No luck: this just leaked air through the mouthpiece opening. How about blowing directly into the melodica? No luck again: the air forces its way out past the reeds. How about using the hard mouthpiece and plugging it (the mouthpiece) with my finger? Ok, some luck. I couldn’t blow any air into this. For practical purposes, I suspect air compression is not a factor in melodica playing.

If you use a soft mouthpiece, then you might increase its volume–you aren’t so much increasing the fluid density of the air as just increasing the volume of air in the system. I suspect that when at least one reed is open, you would be hard pressed to inflate the mouthpiece. An interesting test for this would be to create a mouthpiece from a balloon.

Is the melodica more responsive with a hard mouthpiece? When you blow into a mouthpiece, you are creating a pressure wave. This is exactly the same as a sound wave and it travels at the speed of sound. This speed is only dependent on distance, not on the cross-sectional area of the tube. The time it takes for a reed to sound is based on the pressure wave, not the speed of the air you blow in (in fact, the air speed will increase or decrease as it travels through the system). Will the pressure wave slow down because some pressure is used to expand the tube? I don’t know; it doesn’t seem like it should. The pressure wave might be robbed of some energy which might attenuate the sound.

The balloon experiment sounds more interesting by the moment.

If you have a soft mouthpiece and continue to blow when all reeds are closed, you will increase the volume of stored air. When you press a key, what’s the effect? I don’t know.

I still don’t think there is any significant “responsiveness” difference in soft vs. hard mouthpieces, unless we get to highly stretchable mouthpieces. If I could find a balloon and a way to connect it to my melodica, it might help find the answer.

September 18, 2020 at 6:44 pm #11742Clep

ParticipantI should say that besides the cost (which admittedly isn’t huge, but adds up if you have a bunch of melodicas), getting a replacement stock of tube lets you use different diameters, cut it to your preferred length, maybe have a nicer looking/feeling option, better durability, etc. Or would in theory, anyway, if there were actually options to be found. 🙂

Air is certainly compressible in the simple sense — as the answers to that stack exchange question state, “The term “compressible flow” is rather misleading, but unfortunately, it is what the fluid-dynamics folks have chosen to use.” But yeah we’re agreed that the compressibility (either in terms of flow or compression in terms of density increase) isn’t particularly relevant to tube choice or melodica playing in general.

As far as I understand it, the argument about direct-vs-tube with melodicas has to do with the attack of the sound when a key is already depressed and you sound a note with your tongue. I can’t personally tell a difference in the scenario where pressure is increased and then a key is struck; since the air path is typically open to your lungs anyway, any difference in volume from the tube seems negligible.

I think looking at it as traveling sound waves down the tube is not the best perspective: the speed of sound being so great, that would happen in about a millisecond, and with reeds we’re talking about tonal attack on the order of 10’s of milliseconds. That is, we can probably visualize this as an overall change in pressure in the air in the tube (i.e. simplified to be “instantaneous”).

So in the case where the key is continually depressed and you are using your tongue to make discrete notes, the tube (due to both the air column and whatever stretchiness there is in the tube walls) is going to soften the edge of your pressure changes: it just takes more air from you to cause an equivalent change in pressure in the tube because the volume of air is larger (vs a mouthpiece). I always play with a tube but it seems clear that there is a slightly sharper attack when going through a mouthpiece. It’s a minor difference and doesn’t bother me too much. Others feel strongly about it. It also seems to apply to changes in pressure while a note is sounding (i.e. tremolo): these changes are more readily transferred to the reeds with a mouthpiece, where the tube softens them a little.

September 18, 2020 at 11:14 pm #11743Antonio Freixas

ParticipantGood thoughts. My approach is to try to set up experiments that exaggerate whatever things I’m trying to test for—thus, the idea of using a balloon.

A lot of people were telling me that short mouthpieces (or no mouthpiece) made the melodica more responsive. So I tried a 15′ tube. There was no noticeable response difference.

I’m in the process of setting up a website to discuss melodica physics. I’ll announce it on Melodica World and you’d be welcome to show up and keep me honest. 🙂

[Why not on Melodica World? I’m adding math support, advanced formatting, the ability to edit a post without a time limit, etc.]

September 18, 2020 at 11:21 pm #11744Clep

ParticipantCool, I look forward to checking it out.

November 19, 2020 at 7:14 pm #11863Lamar

ParticipantHi, Clep – Just wanted to let you know that I had some elbows for my Piano 36 made using your hohner_mpiano_36_elbow_v2.sti file and they work great. I put a spare hose from my Suzuki M27C and Hammond 44HPV2 in a coffee cup of hot water for a minute and then stretched it over the fitting. It wasn’t difficult. Thank you.

November 19, 2020 at 7:22 pm #11864Clep

ParticipantAwesome! Glad to hear it was useful. What material did you end up using?

Regarding the rubber tube I’ve been using: the main issue I’m having with it is that the moisture in the tube runs down the smooth internal sides and collects much more easily than in the corrugated tubes. I’m begging to wonder if the reason for the corrugation is less about kink prevention and more about this. I can get through about 1 tune before I have to blow the tube out due to it getting clogged with moisture… it was never that bad with the regular tubes. My suspicion is that the corrugation slows and spreads the moisture. The upside is that the rubber tube may prevent most of the moisture from getting in to the actual melodica (the way I play, it pools at a low point in the tube before the instrument), so I’m not sure which I prefer in the long-term.

I’ve thought about lining the inside of the rubber tube with techflex… if it was the right diameter maybe it could be pulled through and would act to slow the moisture in the same way. But of course it might impede airflow.

And I sometimes think about building a little “spit trap” just before the melodica that could contain the moisture for a longer period.

November 19, 2020 at 10:54 pm #11869Lamar

ParticipantI went for SLS plastic polished white on the elbow. $14 for three, and they sent one extra.

Hehe – you could build a spit trap out of a (largish) plastic pill bottle. Give it that pro look. 🙂

-

AuthorPosts

- You must be logged in to reply to this topic.